O-Ring Sizes

Catalogue

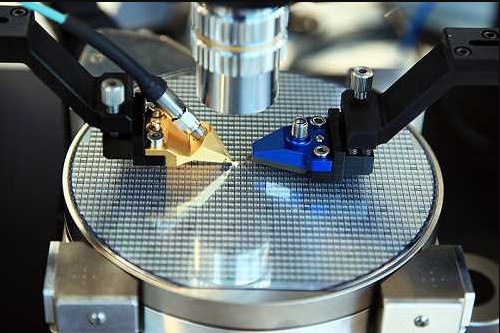

Perfrez® 9021C

Semiconductor grade perfluoroelastomer for use where o-rings and seals are exposed to reactive plasma.

Perfrez® 9021C

A high performance grade of FFKM compound for use under extreme thermal and chemical conditions.

O-Ring Sizes and Material Selection

Download Metric O-Ring Sizes and Standard Sizes Chart (PDF)

O-Ring

Standard Size AS 568A, BS 4518, GB/T 3452.1, JIS B 2401, Metric, Swedish SMS

1586

Of the many kinds of sealing technology available in products

manufacturing and machine design, the use of the o-ring is perhaps the most

common and extensive. O-rings are used in appliances found in our homes as

well as in heavy industrial machines like hydraulic cylinders and jacks.

They are also typically found in many types of hand tools like pneumatic

hammers, drills and air tools.

The selection of the right o-ring

sizes is of critical importance and the sizes of o-rings are determined by

its internal diameter as well as the diameter of its cross section area. The

o-ring, when installed into the mount, should seat nicely and with strict

tolerance within the recess of the mounting. The surface of the mounting

that comes into direct contact with the o-ring should be even so that

pressure on the o-ring is distributed evenly throughout. The o-ring, when

compressed, should exert a pressure against the contact surface of the

mounting of a value that is greater than the pressure of the fluid to be

contained. This is essential for the proper sealing of the fluid and ensures

that no leakage will occur. The selection of the o-ring should therefore be

made with the design and shape or size of the mounting contact surface into

consideration. The wrong size o-ring will result in sealing failure.

Environments where sealing components are subject to abuse include that of

extreme temperatures conditions as well as exposure to corrosive chemical

media. Elastomeric seals have to perform under the most demanding

conditions, and failure would have implications in terms of equipment

downtime, environmental consequences and safety of operation.

Copyright © 2017 Ge Mao Rubber Industrial Co., Ltd.